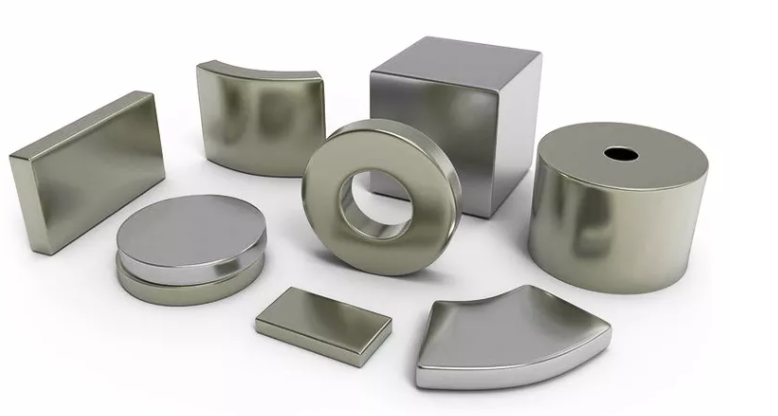

1. Magineti eneodymium anowanzo gadzirwa kubva kune alloy yehupfu ye neodymium, iron, uye boron iyo inosanganiswa pamwe chete mukupisa kukuru uye kumanikidzwa kuumba chigadzirwa chakapedzwa.

2. Musanganiswa weupfu unoiswa mu mold kana mugaba uye inopisa kusvika kune yakakwirira tembiricha kuitira kuti inotanga kunyunguduka uye fuse.

3. Kana zvinhu zvacho zvasvika pakunyungudika, zvinobatwa patembiricha iyi kwenguva yakati kusvika zvaoma kuita chidimbu chimwe chete pasina makwapa kana kutsemuka pakati pezvimedu.

4. Mushure mekunge kusimba kwaitika, magineti inogona kugadzirwa muchimiro chayo chainoda uye saizi uchishandisa maturusi akasiyana-siyana ekucheka akadai semichina yekugaya kana lathes zvichienderana nemashandisirwo ekushandisa.

5. Micheto yemagineti inogona kubva yakwenenzverwa yakatsetseka kana ichidiwa isati yaiswa simbi inodzivirira yakaita senickel kana zinc kuitira kudzivirira ngura.

Rumwe ruzivo rwekugadzirisa, ndapota ona pazasi kuyerera chati:

| Aihwa. | Process Flow | Kugadzira Danho | Technology Operation |

| 1 | Raw Material Inspection | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Rohs Kuonekwa Composition Test Purity Analysis |

| 2 | Raw Material Pre-kurapwa | 4.Sawing- 5. Drying- 6.Impact Cleaning | Sawing Iron Kupisa Mhepo Kuomesa Impact Cleaning |

| 3 | Ingredient Control | 7.Ingredient Control | Weigh Batching Sanganisa Raw Material |

| 4 | Strip Casting | 8.Vacuumizing-9.Melting-10.Casting | Vacuumizing Melting Kunyunguduka Casting |

| 5 | Hydrogen Decrepitation | 11.Pre-treating-12.Vacuumizing-13.Wedzera Hydrogen | Pre-kurapa Vacuumizing Kuparadza neHydrogen |

| 6 | Kugaya | 14.Kupwanya-15.Kugaya-16.Jet Mill-17.Granularity Control | Kupwanya Kukuya Jet Mill Rogular Measurement |

| 7 | Kudzvanya | 18. Hupfu huremu -19.Pre-kudzvanya - 20.Kudzvanya -21. Isostatic pressing | Hupfu huremu Pre-pressing Kudzvanya Isostatic pressing |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Kupisa kurapwa | Vacuumizing Sintering Kurapa kwekupisa |

| 9 | Inspection | 25.BH curve-26. PCT-27. Density test -28.Roughcast Inspection | Magnetic kuyerwa Tembiricha coefficient test PCT Density Measurement Inspection |

| 10 | Machining | 29.Kugaya -30.Waya yekucheka-31.Inner blade cutting | Kukuya Kucheka waya Inner blade kutema |

| 11 | QC muenzaniso bvunzo | 32.QC muenzaniso wekuedza | QC muenzaniso bvunzo |

| 12 | Chamfering | 33.Chamfering | Chamfering |

| 13 | Electroplating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | Electroplating Zn Electroplating NICUNI Phosphating kana Chemical Ni |

| 14 | Coating Inspection | 38.Kukora-39.Kuramba Kuora -40. Adhesiveness-41.-Kushivirira Kuongorora | Ukobvu Corrosion Resistance Kunamatira Kushivirira Kuongorora |

| 15 | Magnetization | 42.Kuongorora Kwakazara- 43.Kumaka- 44.Arraying/Involution- 45.Magnetizing | Complete Inspection Kumaka Arraying/Involution Magnetizing Magnetic Fiux Test |

| 16 | Packing | 46. Magnetic Flux- 47.Bagging- 48. Packing | Bagging Packing |

Nguva yekutumira: Feb-15-2023